Vannamei superintensive culture - ORP an essential tool for water quality monitoring

Vannamei superintensive culture - ORP an essential tool for water quality monitoring and disease prevention

This is not to sell equipment! ORP test is like a pHmeter pocket meter. Cheap and easy to handle, this parameter can show you what is happening in the system very quickly. In vannamei superintensive culture, time and hability to manage fast your corrections is priority. ORP values can tell you if you need to change water, if your aerator are good enough or, your new probiotic is working properly, even if your inlet water quality is poor. In my opinion, sludge sedimentation down the paddle-wheals in growout ponds is the best indication that ORP value can tell you.

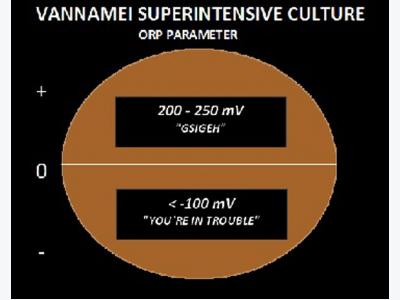

For whom that doesn´t know about ORP, internet have a lot of explanation about it, but is not fully understand it potential as a tool for vannamei culture. In practical matters, this left picture I´ve made to illustrate what is the deal. Positive values, between 200-250mV means "GSIGEH": "Good, Shrimp Is Growing and Everybody is Happy" - this is for stakeholders and CEO´S. For people like me and all people inside the production, it means, amonia is lower, shrimp are healthy and hungry, no overfeeding, oxygen demand is ok and water circulation is fine, suspending solids! Of course all other parameters like shrimp analysis and water chemistry must confirm that, but after you get more familiarity with ORP you will understand what I´m talking about. In another hand, if you get ORP readings less than -100mV it means that something in your system is not working properly and starts the countdown for mortality begins.

Sludge in shrimp ponds or tanks have ORP value around -350mV. If you have deep ponds, more than 1.5m depth, probably you will have sludge sedimentation around the paddle-wheals, air lifts or some places where the wind is blowing. Even with the best water circulation like raceways tanks you do have sludge formation and it will not appear during Inhoff cones samples, unless you check under your aerators, diving in all growout ponds, 2.0m sometimes 2.5m depth twice a day (morning and evening).

When sludge sedimentation rate increase your ORP values start to decrease very fast, due the sludge negative potential, even with Inhoff cones showing little values of TSS as 1.0, 2.0 or 3.0ml/L.

In my experience, when the total solids suspend are increasing during Inhoff samples, in the bottom, the sludge sedimentation reach dangerous quantities that can open the door for diseases and growth problems. We can not quantify how many tonnes of sludge to determine the right ratio between Inhoff sampling and the real number, but if you open your drainage everyday to purge some mud like me, I can tell you that this number is around 10 times more than a Inhoff sample measuring. If you get 2.0ml/l in the cone, probably in the bottom have 20ml/l.

All products that you use have an ORP number after you mix with water. For reference you can see ORP values that can be changed by temperature:

- 10ppm of hipochlorine in 50ppt salt water (to clean): 900mV

- 5ppm of oxygen peroxide in 35ppt salt water (to oxygen problem): 700mV

- 8ppm of dissolved oxygen in 35ppt sterilized salt water (normal air compressed diffuser by micro-bubles hoses): 250mV

- 20ppm of fermented rice bran after 24h in salt water: -350mV

- 1ppm of sludge in salt water: -350mV

- 1ppm of sewer polluted water: -450mV

- Vibrio genus ORP band: -550mV to 100mV

ORP checking should be like pH measuring - twice a day in all steps of your production system - reservoirs, inlet, nursery, growout and outlet. First check early in the morning to see what happened during the nigh time, mostly by molting and feed consumption behavior and prevent the right action during the day, and finally at evening checking, to confirm if your water and feed management got their goals. I hope those information can help you in your management to improve your results. Best regards from Brazil,

Author: Fabio Higa - Aquaculture Consultant

Có thể bạn quan tâm

How to Prevent Early Mortality Syndrome (EMS) in Shrimp Farms

How to Prevent Early Mortality Syndrome (EMS) in Shrimp Farms A new/emerging shrimp disease known as early mortality syndrome (EMS) or acute hepatopancreas necrosis syndrome (AHPNS) has been reported to cause significant

Integrating feed manufacturing into fish or shrimp production operations

Integrating feed manufacturing into fish or shrimp production operations This can be in the form of backward integration into the production of feed or the production of seedstock, or forward integration into processing and marketing

Secondary plant compounds to combat shrimp disease

Secondary plant compounds to combat shrimp disease During the warm season, mortality rates due to Vibriosis can reach 100%. This obviously means that the economic losses are devastating