Recirculation Systems in Aquaculture

Filter System Introduction

Recirculation systems are becoming increasingly popular as they provide a predictable and constant environment for growing fish. Species of fish that can be cultured within recirculation systems include barramundi, Murray cod, Silver perch, snapper and eels plus a number of other species. Recirculation systems also occupy very little area and require little water consumption compared to other forms of aquaculture.

Recirculation systems can be expensive to purchase and operate. For this reason it is usually only economically viable to farm high value species in these systems. Cost of production is generally lower for larger producing systems.

The principal behind recirculation systems is relatively simple however it is important to note that their construction involves some level of technical expertise if they are to succeed. When selecting a supplier or consultant, a potential grower should check their track record for the construction of the recirculation system, after sales service in technical and husbandry advice and ensure that the system will produce the tonnage of fish that has been originally specified by the supplier.

This fact sheet will aim to provide the reader with a brief outline of recirculation systems and their management.

The Principle behind Recirculation

Recirculation systems occupy a very small area and allow the grower to stock fish at high densities and produce high yields per unit area. Recirculation systems are very intensive and therefore require a high level in management of stock, equipment and water quality. Thus it is important to have an understanding of the principles of recirculation systems if the system is to be managed effectively.

A recirculation system is essentially a closed system and involves fish tanks and filtration and water treatment systems. The fish are housed within tanks and the water is exchanged continuously to guarantee optimum growing conditions. Water is pumped into the tanks, through biological and mechanical filtration systems and then returned into the tanks. Not all water is 100% exchanged however as it is difficult to ensure that all waste products are converted or removed by the treatment process. Most culture systems recommend at least 5% to 10% water exchange rate per day depending on stocking and feeding rates.

Recirculation Components

A recirculation fish farming system comprises of a number of major components that are necessary for the management of the system. This includes both site and system components. Please note that different specifications may be required depending on whether you will be using fresh or salt water.

Site Components

The site components include equipment and structures that are not part of the actual recirculation system. The following site components are recommended.

Building

An insulated building or shed is required to protect the recirculation system from external climatic conditions. It will also ensure that the environment in which the fish are cultured is controlled and maintained.

Pump House

The pump house houses the pump that will move water and air through the system. Its purpose is to provide protection for the pump ensuring that it does not come into contact with moisture created from humidity or outside environmental conditions that could potentially damage the pump.

Three Phase Electricity

Electricity is required to run lighting, pumps, filtration systems, heating etc. Three phase power is preferable to single phase electricity due to the high energy consumption requirements from the system.

Emergency Generator

An emergency generator is required just in case mains power is disconnected due to faults, overloading or maintenance. Fish can only survive for very short periods without oxygen or filtration.

Bulk Feed Storage

As large amounts of food are required to feed large numbers of fish, a storage facility is required to protect food from vermin as well as mildew and mould caused by moisture.

Purging and Packaging Facilities

Fish will need to be purged to expel waste matter before they are sent to markets. Fish will need to be processed and packaged if they are not sold to the live market therefore a suitable processing facility that reaches quality control standards will need to be incorporated into the facility.

System Components

System components includes equipment that is directly involved in the culture of the fish within the recirculation system. Major system components include the following.

Oxygen Generator or Source of Aeration

Fish require oxygen to survive. As fish are usually stocked at high densities within the tanks simple aeration using mechanical aeration systems is often not sufficient. Oxygen can be added to the system via liquid oxygen and/or an oxygen generator, to maintain suitable oxygen levels at high stocking rates. Aeration pumps will provide the tanks with both oxygen and water circulation.

Mechanical Filtration

Mechanical filtration removes suspended solids obtained from feces and un-eaten food. Removal of solids is important to ensure that pipes and equipment components do not become clogged with waste material. Decomposing waste matter left in the fish tanks will also consume available oxygen within the water column. There are many various types of mechanical filtration that will filter out different sized particles of waste matter. Some types include drum filtration, screen filtration, foam fractionation, settlement tanks, sand filters just to name a few. Mechanical filters require regular back-flushing to prevent the accumulation of sludge.

Biological Filtration

Fish produce ammonia and nitrites as metabolic waste products which are toxic. These waste products therefore need to be converted into nitrates which are not harmful to the fish.

Nitrification where ammonia and nitrites are converted into nitrates by bacteria via oxidation.

Bio-filters consist of a medium with a large surface area upon which nitrifying bacteria will colonize after a few weeks. These bacteria will convert toxic ammonia and nitrites into non-toxic nitrates via oxidation. This process is known as nitrification. There are a number of different bio-filters on the market and some recirculation systems will often incorporate several into their design.

It will usually take a few weeks to a month before nitrifying bacteria colonize and the bio-filter becomes active. During this time stocking and feeding rates should be reduced.

Sterilization

Water is passed through an ultraviolet sterilizer filter or treated with ozone to destroy any pathogens, parasites and diseases that may be present.

Heating and Cooling

Different culture species have different temperature requirements that must be met to ensure optimum growth rates. Heat exchanges, electric submersion heaters/coolers, or air injection can be used to heat or cool the water. This stresses the importance of housing the recirculation system within a well insulated building to prevent heat loss or gain to or from the outside surroundings and aid in maintaining a constant temperature environment.

Subdued lighting also decreases the stress level in the fish and therefore they are less susceptible to diseases and infections.

Lighting

As the fish are housed within a building, artificial lighting is required to give the fish an impression of a day/night regime. This is to stimulate normal feeding and behavior patterns of the fish to ensure optimum growth.

Subdued lighting also decreases the stress level in the fish and therefore they are less susceptible to diseases and infections.

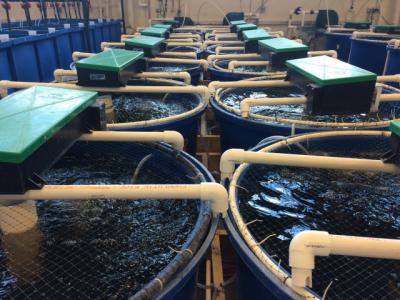

Tanks

Production tanks will very in size and shape however round tanks between 5,000 to 10,000 liters are most commonly used. Tanks need to be non corrosive therefore plastic or fiberglass is recommended. Smooth round tanks with a conical shaped bottom are considered advantageous as this will assist with waste solids disposal during draining.

Some growers will use small cages within the tanks to aid in introducing new stock into the cage. Using this method, growers can isolate and protect newly introduced fingerlings from cannibalism and disease. Alternatively nursery tanks can be incorporated into the system.

Pumps and Pipes

Pumps and pipes are required to move water around the system. It is important to ensure that both pumps and pipes are the correct size to allow adequate flow rates through the tanks and other system components.

Water Quality Management

As fish live and breathe within water it is important that optimum water quality conditions are maintained within the recirculation system especially when fish are stocked at high densities. The supply water carries oxygen to the fish and removes waste products such as feces, ammonium, carbon dioxide and uneaten food. These waste products are removed from the system and transformed into less harmful compounds or concentrations that do not effect the growth or health of the fish.

Water quality must be kept under optimum conditions to ensure the survival of both the culture fish species and the nitrifying bacteria inhabiting the bio-filter. Continuous records of water quality must be regularly taken to control for any changes that may occur. Water quality testing kits or probes are readily available from analytical supply stores however make sure that the equipment will measure within the required ranges and shop around as some can be quite expensive.

Temperature

Maintaining temperature within the optimal range for growth of the selected culture species is vital. Fish grow more rapidly within this range and achieve improved food conversion ratios. Fish are also less stressed when held at their optimum temperatures and therefore become less prone to disease.

Temperature is maintained using artificial heating or cooling as described previously. It is easily measured by using a thermometer.

Oxygen

Dissolved oxygen is perhaps the most critical water quality variable and will depend on water temperatures, stocking and feeding rates and the effectiveness of the aeration installed within the recirculation system. Dissolved oxygen concentrations should be kept above 60% saturation (or around 5ppm) to ensure the survival and growth of the culture species.

The activity of the bacteria within the bio-filter will also depend on the level of dissolved oxygen within the water column and usually become inefficient when oxygen levels fall below 2ppm.

Declining oxygen levels can be caused by a number of factors such as high stocking rates that occur within the recirculation system and the decomposition of organic matter including feces and uneaten food. Low dissolved oxygen can be lethal to the aquaculture species. Some effects include stress, increased susceptibility to disease, poor feed conversion, poor growth and can cause mass mortalities in extreme cases.

Signs of low dissolved oxygen can be detected when fish are observed rising to the surface and gulping air or gathering around the aeration device. There are also oxygen probes available that can effectively measure dissolved oxygen levels and therefore allowing the grower to detect and control dissolved oxygen before it reaches a critical level.

Dissolved oxygen levels can be maintained by incorporating aeration devices into the recirculation system. Oxygen generators are also useful as they will supersaturate the water with oxygen before it enters the grow-out tanks.

pH Levels

The pH is the measure of the hydrogen ion (H+) concentration in the water. The pH scale ranges from 0-14 with a pH of 7 being neutral. A pH below 7 is acidic and a pH of above 7 is basic. An optimal pH range is between 6.5 and 9 however this will alter slightly depending on the culture species.

The pH within recirculating systems tends to decline due to the build up of carbon dioxide (C02) produced by the respiration of fish and bacteria within the bio-filter. Carbon dioxide will react with water to form carbonic acid and therefore push the pH levels downwards. This becomes critical when pH levels reach below 6.5 as the effectiveness of bacteria within the bio-filter becomes void.

Sub-optimal pH also has a number of adverse affects on the culture species. It can cause stress, increase susceptibility to disease, low production levels and poor growth. Signs of sub-optimal pH include increase mucus on the gill surfaces of fish, damage to the eye lens, abnormal swimming behavior, fin fray, poor phytoplankton and zooplankton growth and can even cause death.

pH can be maintained within the recirculating system by adding buffering agents such as sodium bicarbonate or calcium carbonate, and by aerating the water which reduces the buildup of carbon dioxide. Water should be checked for pH almost daily within a recirculating system by using pH probes or special testing kits that are available from water analysis suppliers.

Carbon Dioxide

Carbon dioxide is produced by the respiration of fish and bacteria within the system. If carbon dioxide levels reach high levels it can cause respiratory problems as it will interfere with oxygen uptake. High carbon dioxide concentrations within the water column can also cause pH levels to decrease as mentioned previously.

Carbon dioxide can accumulate within recirculation systems if it is not removed. This can be achieved by aeration.

Water Alkalinity and Hardness

Alkalinity refers to amount of carbonates and bicarbonates in the water and water hardness refers to the concentration of calcium and magnesium. As calcium and magnesium bond with carbonates and bicarbonates, alkalinity and water hardness are closely interrelated and produce similar measured levels.

Waters are often categorized according to degrees of hardness as follows:

0 - 75 mg/I = soft

75 - 150 mg/I = moderately hard

150 - 300 mg/I = hard

over 300 mg/I = very hard

It is recommended that alkalinity and hardness levels are maintained above 50 mg/I which provides a good buffering (stabilizing) effect to pH swings that occur in ponds due to the respiration of fish and bacteria. However high water hardness can cause a build up of calcium deposits on pipes and fitting which can be difficult to remove.

Nitrogenous Wastes

Ammonia is the main nitrogenous waste that is produced by fish via metabolism and is excreted across the gills as ammonia gas. Ammonia can also be produced from the decomposition of organic wastes resulting in the breakdown of decaying organic matter such as animals and uneaten food.

Ammonia is present in two forms in water - as a gas NH3 or as the ammonium ion (NH4+). Ammonia is toxic to culture animals in the gaseous form and can cause gill irritation and respiratory problems.

Ammonia within recirculation systems is broken down by the bacteria within the bio-filter via nitrification as mentioned previously. Ammonia levels will depend on the temperature of the water and its pH. For example at a higher temperature and pH, a greater number of ammonium ions are converted into ammonia gas thus causes an increase in toxic ammonia levels within the water.

If ammonia levels become elevated it is important to check the effectiveness of the bio-filter within the recirculation system. Bio-filters can fail due to mechanical failure or biological failure caused by the inhibition of bacterial activity. Bacterial activity can be reduced due to toxicity from chemicals, natural aging, lack of oxygen, pH, etc. It is important to remember that bacteria are living organisms and require just as much care as the culture species. Bacteria survival is extremely important as it ensures the health, growth and survival of the culture species.

If high levels of ammonia are present within the pond's water, a number of measures can be taken. These include:

reduce or stop feeding

flush the tanks with fresh water

reduce the stocking density

increase aeration

in emergencies - reduce the pH level

The amount of ammonia present in the water can be calculated by recording the total ammonia¬nitrogen (TAN), pH and temperature (Table 1).

For example to obtain the concentration of NH3: Water at pH 8.4, 28°C and 2mg/1 of TAN (sampled measurement) contains 15% NH3 (from table). Therefore 2mg/1 x 15% / 100 = 0.3 mg/I of NH3. Alternatively, ammonia testing kits and probes can be purchased from analytical supply stores.

Table 1: Percentage of TAN in the toxic unionized form NH3 at different temperature and pH levels. Boyd (1982) “Water quality management for pond fish culture”.

Solids

Solid wastes, or otherwise known as particulate organic matter often consists of feces or uneaten food. A build up of solid wastes within the system should be prevented as it can cause oxygen depletion and ammonia toxicity when it decomposes. Mechanical filtration and water exchange will remove the majority of organic matter from the system.

Organic wastes are present in three main forms in the recirculation system:

Settling solids - accumulate on the bottom of the tank

Suspended solids - float in the water column and will not settle out of water

Fine and dissolved solids - float in the water column and can cause gill irritation and health damage to fish

Dissolved Ions

Dissolved ion concentration should be checked before a water source is used as dissolved ions can be difficult to remove. This is particularly relevant when bore water is used as this source can sometimes be high in dissolved ion concentration which can effect the respiratory capacity of the fish. See below for some of the recommended levels.

NOTE: Boyd (1998) “Water Quality for Pond Aquaculture"

Stock Management

Culture stock must be managed carefully to ensure the health, survival and growth of the animals. This is particularly important in recirculation systems as the fish are held under very high density conditions.

Stocking

It is important to consider the behavior and ecology of a species before deciding which species to culture. Some of the characteristics that are required include:

Breeding technology

Availability of fingerlings

Schooling fish

Known culture technology

Will feed on a commercial pellet

Rapid growth rates

Market acceptability

Stocking rates will depend on the species of fish that are to be cultured.

Grading

Grading is a particularly important exercise when farming fish using a recirculating system. Fish will grow at varying rates therefore it is necessary to separate the faster growing fish from the slower growing fish to prevent cannibalism.

The frequency of grading will depend on the species of fish however grading is generally performed more frequently when the fish are younger.

Feeding

Fish feed on zooplankton during the larval stage and are then weaned onto dry pellets when they reach fingerling status. The majority of fish are purchased as weaned fingerlings however it is important to check this with the supplier.

Feeding rates and the type of feed will depend on the species of fish that is to be cultured. It is important not to overfeed as this can cause oxygen depletion due to a build up of uneaten food in the tanks.

Fish can be fed manually and are usually supplied pellets once or twice or sometimes three times per day. Pellets are scattered over the surface of the water in the tanks.

There are also a number of automatic feeders that can be installed. Automatic feeders are useful as they require less manual labor than manual feeding. They also prevent "ammonia spikes" which occur after the fish are fed. Ammonia levels remain relatively constant when automatic feeders are used as fish are fed continuously rather than being concentrated at certain intervals. This creates less pressure on the bacteria within the bio-filter to convert small amounts of ammonia continuously rather than large amounts of ammonia in one hit.

Some examples of automatic feeders include belt feeders where feed is placed within a storage area and a conveyor belt drops pellets into the water at regular intervals. Demand feeders are also available where fish are fed by triggering the feed disposal when required.

Disease and Stress

As fish are held at high densities within the recirculation system they are more at risk at becoming stressed and therefore prone to disease. It is important to monitor fish health continuously as if a disease outbreak does occur it can spread extremely rapidly throughout the culture tank. Fish farmers usually ensure that tanks can be isolated from one another to prevent a disease from spreading throughout the entire system.

Harvesting and Purging

When fish have reach market size, they will require harvesting and purging before they are transported to their respective markets.

Harvesting is done using nets which are dragged through the tanks. This must be achieved as thoroughly and effectively as possible to prevent further stress on the animals.

Once the fish have been removed from the culture tanks they are placed within purging tanks which are filled with clean and fresh water. Fish are kept within the purging tanks for a few days to a week. This ensures that the "off-flavor" that is often associated with farmed fish is removed and thus will increase their market acceptance.

Marketing

Marketing is an important feature of fish farming which is often overlooked. It must be determined before a fish is farmed where it is to be sold, how it is to be sold and how much money will the fish fetch.

Market prices obtained for the fish must be higher than the overall cost of production in using the recirculating system to culture the fish otherwise no profit will be made. Remember money is made in aquaculture by selling fish and not growing fish.

A Few Notes about System Design

The design of recirculating aquaculture systems is complex and for the system to work effectively, the correct components and their specifications must be used. Please be aware that components and specifications will be different for both freshwater and saltwater systems and therefore you can not change over a system from freshwater to saltwater without major changes to the design. For example components that do not rust must be used and a larger bio-filter is required in saltwater systems. Recirculating aquaculture systems are a major investment and careful consideration must be undertaken when purchasing one. A checklist has been constructed to assist in making the right choices. If a copy has not been included with this fact sheet we highly recommend you obtain one through contacting PIRSA Aquaculture SA.

Rules and Regulations

Before someone can venture into finfish farming using a recirculating system, an aquaculture permit must be obtained through the Aquaculture SA within Primary Industries and Resources South Australia (PIRSA). This permit will record the applicant as a registered fish farmer and therefore enable them sell their produce.

Before a permit may be granted by the Aquaculture SA for land-based applications it may be required that approval be sought by the Department of Environment, Heritage and Aboriginal Affairs (DEHAA), the Environment Protection Authority (EPA) and local councils.

Disposal of waste water produced from fish farms using recirculating systems is an important environmental issue as is strongly regulated. Waste water is extremely high in nutrients and if released into natural water ways, it can cause algae blooms including blue-green algae which is toxic to many organisms. Regulations suggest that waste water should be pumped into settlement dams or used for irrigation. Some farmers are exploring the idea of using waste water for hydroponics which will strip the water of nutrients and will also provide the fish farmer with an alternative crop

Related news

A new diffused-aeration concept for aquaculture

A new diffused-aeration concept for aquaculture Dissolved oxygen (DO) is a major limiting factor in aquaculture and sub-optimal levels may limit production.

Diffused-Air System Improves Oxygen Levels In Sea Cage Culture

Diffused-Air System Improves Oxygen Levels In Sea Cage Culture Dissolved oxygen in culture water is considered one of the dominating limiting factors in aquaculture.

Dissolved-Oxygen Concentrations In Pond Aquaculture

Dissolved-Oxygen Concentrations In Pond Aquaculture Low dissolved-oxygen concentration is recognized as a major cause of stress, poor appetite, slow growth, disease susceptibility and mortality in aquaculture