NIRS technology ensures shrimp feed quality at farm level

Technology successfully applied in Brazil

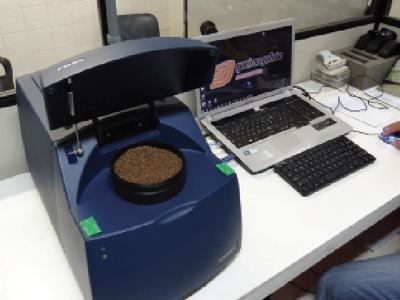

NIRS can perform multiple analyses within minutes. The NIRS concept is based on prediction models using calibration curves for desired nutrients.

The nutrient quality and biological performance of shrimp feeds result from the nature and quality of the raw materials used in their composition, as well as the formulation tools, equipment and manufacturing methods used in their production.

Feed plants ensure the quality of their feed by adhering to strict quality controls. This starts with the purchasing department, which works with suppliers to set quality standards for raw materials. Quality adherence continues through controls that certify the physical and chemical qualities of finished feeds. However, on a daily basis, feed plants usually deal with several types of raw materials, formulations and feeds for different animals, which can lead to quality issues and nutrient variations not easily detectable at the manufacturer level, let alone by farmers.

Near-infrared spectroscopy

From the farmer’s perspective, little can be done to deal with these possible variations in feed quality other than making the best selection of feed suppliers while continuously evaluating farm results. However, near-infrared spectroscopy (NIRS), a new quick evaluation technology, has been successfully applied in Brazil to ensure feed quality standards at the farm level.

Potiporã Aquacultura, the largest shrimp farm in Brazil, uses NIRS to evaluate the feed it acquires from third parties. Located in Rio Grande do Norte, Brazil, Potiporã is part of the vertically integrated maturation, hatchery, growout and processing operations owned by Queiroz Galvão Alimentos S.A. The 960-ha farm used 4-ha growout ponds to produce 7,000 metric tons (MT) of Pacific white shrimp (Litopenaeus vannamei) in 2014.

Wet chemistry versus NIRS

When choosing a method to assess feed quality at a shrimp farm, one should address its accuracy, speed, cost, repeatability and ease of operation. Traditional wet chemistry methods meet some of these criteria. However, they often take considerable time and require physical space, as well as qualified personnel to handle the specialized equipment and reagents. Such conditions make this method impractical for the quick decision making often required by large-scale commercial shrimp operations.

NIRS can perform multiple analyses within minutes. The NIRS concept is based on prediction models using calibration curves for desired nutrients. The curves are based on a database previously developed from chemical analyses of a wide and diversified universe of samples. Feed is analyzed by collecting a ground or unground sample of about 100 g, followed by its exposure to the equipment, which provides results within seconds.

Calibration curves are usually designed to estimate moisture, crude protein, fat, crude fiber, ash, calcium and phosphorus values for selected raw materials. At Potiporã farm, calibration curves were initially standardized with 460 feed samples individually analyzed by wet chemistry.

In addition to the investment involved in the acquisition of NIRS equipment, there are also costs to develop these calibration curves. This effectively limits the application of NIRS to large-scale aquaculture operations that rely on third-party feed suppliers.

Feed quality standards, protocol for analyses

Potiporã uses one starter feed with two particle sizes and two types of growout feed, one for semi-intensive ponds stocked at 30 shrimp/m2 without mechanical aeration and another for intensive conditions with mechanical aeration and up to 100 shrimp/m2. Therefore, quality standards were set for each feed type.

Aerial view of shrimp growout ponds at Potiporã Aquacultura. It is the largest shrimp farm in Brazil.

In Brazil, feed bags carry a tag indicating the minimum and maximum levels of basic nutrients. Originally, Potiporã adopted these quality standards set by the feed manufacturer, allowing a variation of ± 5.5 percent.

To establish levels within ranges that would not compromise the nutrient balance of the diets, feed quality standards were revised after 800 readings performed by NIRS. In this case, a narrower variation of ± 3.0 percent was set for each parameter (Table 1).

Nunes, Table 1

| Nutrient Composition % | (% of diet, as-is basic) | ||

| Parameter | Starter diet | Semi-intensive diet | Intensive diet |

| Crude protein (min.) | 40.0 | 35.0 | 38.0 |

| Digestibility (min.)* | 80.0 | 80.0 | 80.0 |

| Fat (min.) | 10.0-11.0 | 9.0-10.0 | 2.0-3.0 |

| Total fiber (max.) | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 |

| Ash (max.) | 1.3 | 1.2 | 1.3 |

| Calcium (min. – max.) | 4.0 | 4.0 | 4.0 |

| Total phosphorous (min.) | 12.0 | 11.0 | 12.0 |

| Moisture (max.) | 8.0-12.0 | 8.0-12.0 | 8.0-12.0 |

Chemical quality standards for shrimp feeds used by Potipora Aquacultura (Variation = +/- 3.0%)

*Digestibility in pepsin at 0.0002%

All feed that enters the farm is analyzed before truck unloading and storage. If the product does not meet the established quality standards, feed is rejected, and the supplier is informed. If feed falls into desirable standards, it is unloaded.

Perspectives

Driven by availability due to shifts in prices and/or seasonality, seemingly simple changes of ingredients or their inclusion levels in a feed formula can lead to significant changes in key dietary nutrients. Set minimum quality standards and nutrient compositions for raw materials should be analyzed upon arrival of feed at the plant to allow adjustments in formulations before feed manufacturing.

However, continuous sampling and analysis of all raw materials may not always be feasible, and formulators often need to rely on expected values from a database. This can negatively affect the nutrient value of a feed and limit the ability to modify the amount and bioavailability of critical nutrients such as protein and amino acids.

The unique feed quality assessment program developed by Potiporã has safeguarded the enterprise from potential financial losses associated with undesirable feed quality. The continued surveillance through NIRS has reduced the uncertainties and variables that affect shrimp farming.

With a comprehensive database on hand, the company has established a feed purchasing policy aligned with farm needs for nutritious feed products. Calibration curves are now under development to allow NIRS feed analysis for essential amino acids and fatty acids.

Alberto J. P. Nunes, Ph.D.

LABOMAR – Instituto de Ciências do Mar, Av. da Abolição, 3207 – Meireles, CEP 60165-081 Fortaleza, Ceará, Brazil

Thiago Costa Paiva

Sergio de Lima Cavalcanti, Queiroz Galvão Alimentos S.A. Pendências, Rio Grande do Norte, Brazil

Related news

Critical decisions for shrimp harvesting and packing, Part 2

Critical decisions for shrimp harvesting and packing, Part 2 The quality shrimp have at the moment of harvest represents a significant investment in time and resources, and subsequent steps must be adequately planned

Critical decisions for shrimp harvesting and packing, Part 3

Critical decisions for shrimp harvesting and packing, Part 3 Final stages include receiving protocols at processing plants, weighing, grading and freezing. This quality must be preserved through the processing and packing

Testing shrimp growth in different biofloc systems

Testing shrimp growth in different biofloc systems Pacific white shrimp reared in biofloc systems can consume biofloc particles, potentially reducing feed costs while recycling nutrients.